The Missing Ingredient

Picture this: You’re the VP of Operations at a regional food manufacturer. Eight production lines churning out products 24/7. Commodity prices fluctuating daily. And when someone asks “What’s our margin on the new product line?"—silence.

That was Chicago Co’s reality.

They’d built a successful business on great recipes and loyal customers. But as they scaled, the cracks started showing. Production data lived in one system. Financial data in another. Inventory counts that never quite matched. And a planning team making decisions based on spreadsheets that were outdated the moment they were created.

They were stuck.

We knew we were profitable. We just couldn’t tell you which products were carrying which ones.

That’s the kind of blind spot we walked into. This wasn’t about fancy analytics. This was about survival in a razor-thin margin business.

The Problem Beneath the Surface

When we sat down with Linda from Finance and Roberto from Production, the scope of the challenge became clear. It wasn’t just about reports. The problems ran deep:

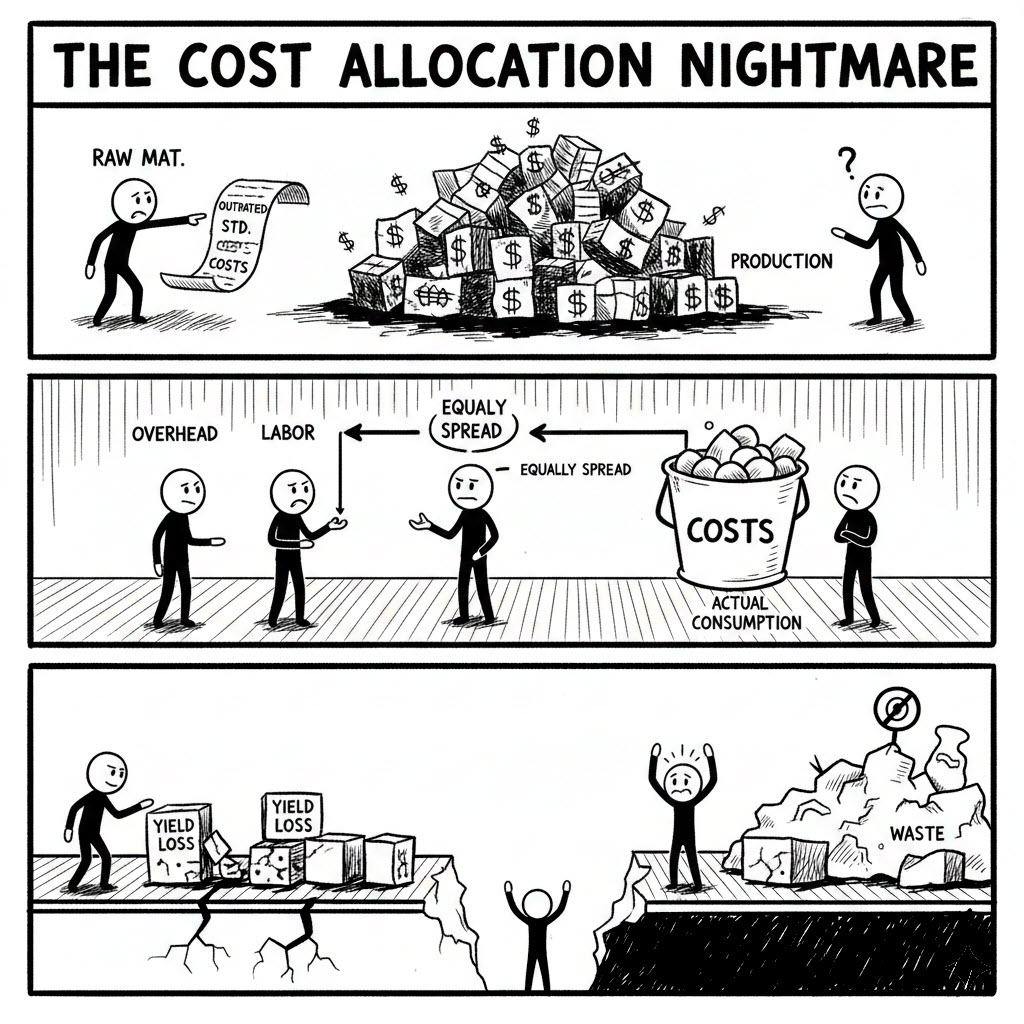

The Cost Allocation Nightmare

- Raw material costs allocated using outdated standard costs

- Labor and overhead spread evenly instead of by actual consumption

- No visibility into yield loss or waste by production line

The Inventory Reconciliation Maze

- Physical counts that never matched system quantities

- Batch tracking that broke down during high-volume production runs

- Expiration dates tracked in spreadsheets separate from the ERP

The Pricing Dilemma

- Customer contracts with different pricing tiers

- Promotional pricing that wasn’t reflected in margin analysis

- No way to see true profitability by customer or channel

As Linda put it: “We price based on what we think our costs are. But by the time we know our actual costs, we’ve already committed to the price.”

The existing system just wasn’t built for this complexity.

Enter the Creators

This is where Bish and Bhavana stepped in.

Their approach wasn't to throw technology at the problem. It was to understand it first. Hours of calls. Plant floor visits. Questions like "What happens when a batch fails quality control?" and "Walk me through how you calculate yield."

The Key Insight

The breakthrough came when we realized the core issue: Chicago Co didn't need more reports. They needed timely reports, with accurate costs, delivered before pricing decisions.

Bhavana proposed a three-pronged approach:

- Actual Cost Tracking replacing standard cost allocations with real consumption data

- Yield Analysis to identify waste and loss by production line

- Customer Profitability showing true margin after all discounts and promotions

No more guessing at margins. No more pricing blind.

The Proposed Solution

We invoked the 5 Standards of the Report Factory:

1. ETL Plumbing

Solidifying the data pipeline from D365 F&O to Microsoft Fabric. Production data, financial data, and inventory data—all flowing into one place.

2. Data Modeling

A single source of truth. One data model that connected production batches to financial transactions. We built custom views to calculate actual costs at the batch level.

3. Visual Hierarchy

Flyovers for executives who need margin summaries. Drill-downs for production managers who need line-level details. Everyone sees what they need to see.

4. Maintenance

Systems that can be managed even if outsourced. Documentation. Standards. Repeatability. No platform lock-in.

5. Portability

Architecture that can be moved between platforms without losing functionality.

The Transformation

We found out one of our “best sellers” was actually losing money. That one insight paid for the entire project.

Here’s what changed:

Before:

- 8 production lines, 8 different cost assumptions

- Margin analysis that took weeks and was always outdated

- Pricing decisions based on gut feel

- No visibility into customer-level profitability

After:

- Real-time actual cost tracking by batch

- Daily margin visibility by product and customer

- Yield analysis identifying waste reduction opportunities

- Pricing decisions backed by data

The moment of truth came when they discovered a high-volume product line was actually underwater after accounting for true costs. Roberto’s reaction?

“We’d been pushing sales on that product for two years. Two years of thinking we were winning.”

That’s the sound of someone seeing clearly for the first time.

The Bigger Picture

What Chicago Co taught us goes beyond reporting. It’s about the future of how manufacturers operate.

As Joe shared during one of our sessions:

I don’t think there’s going to be a reporting department in the future. What’s going to happen is that people will write an operating system that runs the business. And reporting is just for the AI agents, it’s just for the operating system.

The materiality of stopping and thinking—of pausing to look at printouts and decide what to do—is a massive cost to any organization. Chicago Co’s transformation is a step toward a future where the right information flows to the right decisions automatically.

Your Turn

Chicago Co’s journey from stuck to unstuck took weeks, not months. The investment was measured in thousands, not hundreds of thousands.

Every organization has a story. What’s yours?

Are you:

- Flying blind on product margins?

- Struggling with cost allocations that don’t reflect reality?

- Making pricing decisions without knowing true costs?

The water might be rising. But you don’t have to stay stuck.